What a great xmas we had! (At least, from my standpoint.) My daughter cleaned, my son's girl friend cooked, all I had to do was sit and eat and enjoy family. I think I am going to retire from hosting holidays.

Knitting: This is about all I am doing, as I race toward the sock deadline. Usually, I knit a color band on each sock each day, but I've had to double my output in order to reach the deadline. I should be hitting the cuffs around Jan 1, plenty of time for a Jan 6 delivery date.

Needle felting: I placed an order with Living Felt, so once that arrives, progress on Dill will continue.

My son and his girl friend gifted me with the best ugly sweater ever!

I plan to wear it to January fiber meetings, as I don't want to save it until next xmas.

Saturday, December 28, 2019

Sunday, December 22, 2019

Like a turtle

The first week of recovery is going a bit more slowly than I expected. I slept a lot for a couple of days before realizing I was running a low grade fever. The phone nurse assured me this was normal. I quit the rx pain meds and switched to Tylenol, in case they were contributing to my grogginess. I am getting around better, putting more weight on my "bad" leg, but still have a ways to go. Thank goodness for great caregivers!

Knitting: That is all I have felt up to doing. The L-Bag drags on (and on and on). Can't wait for that to be done. The socks are trucking along, too.

Xmas will be at my house, primarily because neither of my kids has a bathroom on the main floor of their houses. But I don't have to do anything but relax in the (elevated) recliner. Temps are going to be in the 50's - not very xmas-like, but at least travel should be clear and dry.

Enjoy your holidays, however you celebrate!

Knitting: That is all I have felt up to doing. The L-Bag drags on (and on and on). Can't wait for that to be done. The socks are trucking along, too.

Xmas will be at my house, primarily because neither of my kids has a bathroom on the main floor of their houses. But I don't have to do anything but relax in the (elevated) recliner. Temps are going to be in the 50's - not very xmas-like, but at least travel should be clear and dry.

Enjoy your holidays, however you celebrate!

Tuesday, December 17, 2019

Quick update

I'm home. Yesterday's surgery went well, despite my hip being worse than expected. In recovery, I was crying because my hip hurt so much, but after several doses of morphine, things were under control and just got better. Today the PT and OT people thought I was ready to go home, the doctor not so much. However, I talked him into it.

Parkview has a reputation for collecting the most money from insurance companies, despite being a not-for-profit hospital system in an area where the cost of living is relatively low. The extra money goes into several foundations that funnel money back into the community. I feel I received excellent care BUT I'm sure they could pay their employees better, especially those lower on the scale. They could provide more benefits, too.

I did absolutely NO knitting while there. Since I have a sock deadline, I will have to include them in my daily knitting rotation. I don't think I will be able to spin for a while, so that should work out fine.

Parkview has a reputation for collecting the most money from insurance companies, despite being a not-for-profit hospital system in an area where the cost of living is relatively low. The extra money goes into several foundations that funnel money back into the community. I feel I received excellent care BUT I'm sure they could pay their employees better, especially those lower on the scale. They could provide more benefits, too.

I did absolutely NO knitting while there. Since I have a sock deadline, I will have to include them in my daily knitting rotation. I don't think I will be able to spin for a while, so that should work out fine.

Saturday, December 14, 2019

Two more days

Two days from now I should be feeling... different. The hip pain should be gone, replaced by surgery pain and hopefully some good drugs. I've been a good patient, following all the rules and doing my exercises, etc. My general philosophy is "Hope for the best, plan for the worst" but when I think that things could get worse instead of better, I start sobbing. So best not to think like that!

Knitting: Still plowing ahead on the L-Bag. The shaping part is longer than I realized, but at least the stitch counts are still okay.

Spinning: Still spinning that luscious light gray Shetland top. The wool looks almost white but once it is spun and plied, it looks very gray. I plan to overdye it... with purple?

Weaving: Struggling a bit with the online weaving class, partly because I don't have the same equipment, partly because I don't have a good work area set up where I can view the videos AND work on the loom. My SO moved a table into my studio where the light is better, so hopefully that will help.

Needle felting: My granddaughter and I tried using my drum carder to blend some of the needle felting wool to create a yellow green for Dill's skin, BUT the fibers are so short they pilled a lot. Also, we are not very satisfied with the color. I am going to order some in the right color from Living Felt. While looking at their web site, I noticed some 2-D needle felting kits. I think one of those will be finding its way here as well.

I've been ruminating on how bad habits are broken and good ones made. It comes down to friction. To erase a bad habit, one increases the friction. For example, if you want to cut down on junk food, make a "rule" that it may be eaten but only if it is homemade (by you, of course). The opposite applies to good habits: reduce the friction. When I am done spinning for the day, I make sure the wheel is set up so that the next time, all I have to do is sit down and start; that has worked well for me. One bad habit I would like to erase is how I tend to get out a project to work on, then leave it out until pretty soon all the horizontal surfaces in my living areas are cluttered with half finished projects. A corollary to this bad habit is the necessity for the projects to be easily accessible in order to continue to work on them. THAT will take some organization!

Knitting: Still plowing ahead on the L-Bag. The shaping part is longer than I realized, but at least the stitch counts are still okay.

Spinning: Still spinning that luscious light gray Shetland top. The wool looks almost white but once it is spun and plied, it looks very gray. I plan to overdye it... with purple?

Weaving: Struggling a bit with the online weaving class, partly because I don't have the same equipment, partly because I don't have a good work area set up where I can view the videos AND work on the loom. My SO moved a table into my studio where the light is better, so hopefully that will help.

Needle felting: My granddaughter and I tried using my drum carder to blend some of the needle felting wool to create a yellow green for Dill's skin, BUT the fibers are so short they pilled a lot. Also, we are not very satisfied with the color. I am going to order some in the right color from Living Felt. While looking at their web site, I noticed some 2-D needle felting kits. I think one of those will be finding its way here as well.

I've been ruminating on how bad habits are broken and good ones made. It comes down to friction. To erase a bad habit, one increases the friction. For example, if you want to cut down on junk food, make a "rule" that it may be eaten but only if it is homemade (by you, of course). The opposite applies to good habits: reduce the friction. When I am done spinning for the day, I make sure the wheel is set up so that the next time, all I have to do is sit down and start; that has worked well for me. One bad habit I would like to erase is how I tend to get out a project to work on, then leave it out until pretty soon all the horizontal surfaces in my living areas are cluttered with half finished projects. A corollary to this bad habit is the necessity for the projects to be easily accessible in order to continue to work on them. THAT will take some organization!

Sunday, December 08, 2019

Hanging in there... barely

Pre-op prep for hip replacement surgery includes a 10-day moratorium on any useful pain reliever one has found. In other words, I'm down to Tylenol and Icy Hot, which quite frankly is not enough. My daughter came over today to vacuum and mop, clean litter boxes and pick up dog poop, but I keep finding little extra things she did along the way. Tomorrow my SO will help me prep the house and run a few errands. I'm so thankful to have help!

Knitting: I am back to the shaping bit for the L-Bag, and with the correct number of stitches this time. Whoo-hoo!

Spinning: I'm continuing to spin the light grey Shetland and have 3-plied two skeins. It is turning out nice but I need a LOT more to do the Main Squeeze Cardigan.

Needle felting: Dill has four legs now, needs just a tail. Then my granddaughter will add the green skin and markings.

Weaving: I decided to treat myself to an online tapestry weaving class, to distract myself while I recover from the surgery. This particular class has three parts, but I purchased only part 1, to see if I like it. I also refrained from investing in a Mirrix loom ($$$) and from purchasing the recommended fiber. Instead, I will use the PVC pipe loom from the tapestry class I took at the Michigan Fiber Festival and fiber I already have on hand (and there is PLENTY of that!)

Besides fiber arts, I have been reading a lot and watching some Netflix. I highly recommend Abstract: The Art of Design. It is very inspiring.

Knitting: I am back to the shaping bit for the L-Bag, and with the correct number of stitches this time. Whoo-hoo!

Spinning: I'm continuing to spin the light grey Shetland and have 3-plied two skeins. It is turning out nice but I need a LOT more to do the Main Squeeze Cardigan.

Needle felting: Dill has four legs now, needs just a tail. Then my granddaughter will add the green skin and markings.

Weaving: I decided to treat myself to an online tapestry weaving class, to distract myself while I recover from the surgery. This particular class has three parts, but I purchased only part 1, to see if I like it. I also refrained from investing in a Mirrix loom ($$$) and from purchasing the recommended fiber. Instead, I will use the PVC pipe loom from the tapestry class I took at the Michigan Fiber Festival and fiber I already have on hand (and there is PLENTY of that!)

Besides fiber arts, I have been reading a lot and watching some Netflix. I highly recommend Abstract: The Art of Design. It is very inspiring.

Saturday, November 30, 2019

Belated Thanksgiving greetings

I hope you all had a satisfying Thanksgiving Day. My daughter hosted, cooked all the family favorites (and then some), and I left in a food coma. My SO was sick with the flu, so he missed out (and we missed out on getting exposed to his germs). My ex was there, weird as ever, and my son and his girl friend. Then there were my daughter's husband's family, who mainly kept to themselves because we were hogging the dining room table. No drama, no angst, which made it perfect.

Knitting: Turned the heels on the socks; now they will remain mostly dormant so I can take them to the hospital as an activity to keep me occupied between physical therapy sessions. I am almost back to the shaping part of the L-Bag, and I am liking it much better.

Spinning: I waffled about what to spin next, decided it should be something luscious and fun, so today I started spinning some Shetland top (from Jamiesons via Little Shop of Spinning). Yum! So smooth with a nice long staple. I have about a pound of it, plan to spin an ounce a day, then buy more. Shetland is supposed to be pill-resistant.

Needle felting: My granddaughter finished decorating the felted xmas tree ornament; the bunny Peep has some sparkly fuzz now but needs details. Dill is coming along; I'll finish the core and then my granddaughter can add the color.

Still not back to weaving. And there is a fleece sitting in a big plastic garbage bag not far from this desk, just waiting to be flicked and carded. I don't understand people who claim retirement is boring - there is so much to do!

Knitting: Turned the heels on the socks; now they will remain mostly dormant so I can take them to the hospital as an activity to keep me occupied between physical therapy sessions. I am almost back to the shaping part of the L-Bag, and I am liking it much better.

Spinning: I waffled about what to spin next, decided it should be something luscious and fun, so today I started spinning some Shetland top (from Jamiesons via Little Shop of Spinning). Yum! So smooth with a nice long staple. I have about a pound of it, plan to spin an ounce a day, then buy more. Shetland is supposed to be pill-resistant.

Needle felting: My granddaughter finished decorating the felted xmas tree ornament; the bunny Peep has some sparkly fuzz now but needs details. Dill is coming along; I'll finish the core and then my granddaughter can add the color.

Still not back to weaving. And there is a fleece sitting in a big plastic garbage bag not far from this desk, just waiting to be flicked and carded. I don't understand people who claim retirement is boring - there is so much to do!

Sunday, November 24, 2019

Slub, slub, slub

As I have mentioned before, I have been playing with spinning slubby yarn. New spinners have no trouble doing this - it is what beginning spinning looks like, fat and thin. But try doing it on purpose! And in a not-random way! It is not easy.

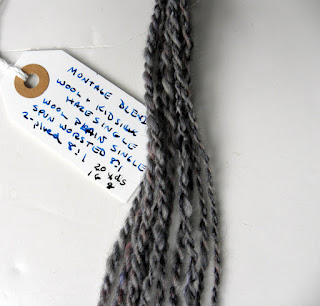

"They" recommend using top for this endeavor, but I stubbornly stuck with some roving I had on hand, a "Montage Medley" which is a fancy term for "mill ends". I think it was made by Ashford. If I decide to make more slubby yarn in the future, I will use top and see just how much easier that is (and whether the result is better) .

While spinning some of the slubby, I wrapped it at the same time with navy thread. To do this, the thread has to be held above the twist, so that it wraps. In a way, it is like spinning and plying at the same time. I also spun some plain singles from the Montage Blend, to ply with the slubby singles.

When I tired of spinning slubby, I still had a lot of the Montage Medley left, so I tried spinning some with white silk and some with navy Kidsilk Haze. The idea was that the silk and Kidsilk Haze would be mostly buried in the MM, so I held it below the twist, with the fiber. My results varied, with the silks showing some of the time.

There was plenty of single yarn, so after plying the slubby single with plain single, to create a two-ply, I three-plied the plain single, silk single, and Kidsilk Haze single. Of course, I ran out of one of those singles before the others, so I made a two-ply with the plain and Kidsilk Haze until I ran out of the latter, then finished with a two-ply of just the plain.

A new (to me) thing I tried was steaming the finished yarn instead of soaking it, to set the twist. My SO had loaned me his handheld steamer and I watched a couple of YouTube videos in preparation. I guess it worked okay - my yarn tends to be rather balanced once I am done plying, but it did feel fuller when I finished.

I ended up with a lot of yarn:

So what shall I make with all this? The roving is soft so the slubby yarn is soft, so it might be a nice woven or knitted scarf. The yarns with the silk and Kidsilk Haze has a tougher feel, though. I will have to let the yarn "age" a bit while I consider my options. Any suggestions?

"They" recommend using top for this endeavor, but I stubbornly stuck with some roving I had on hand, a "Montage Medley" which is a fancy term for "mill ends". I think it was made by Ashford. If I decide to make more slubby yarn in the future, I will use top and see just how much easier that is (and whether the result is better) .

While spinning some of the slubby, I wrapped it at the same time with navy thread. To do this, the thread has to be held above the twist, so that it wraps. In a way, it is like spinning and plying at the same time. I also spun some plain singles from the Montage Blend, to ply with the slubby singles.

When I tired of spinning slubby, I still had a lot of the Montage Medley left, so I tried spinning some with white silk and some with navy Kidsilk Haze. The idea was that the silk and Kidsilk Haze would be mostly buried in the MM, so I held it below the twist, with the fiber. My results varied, with the silks showing some of the time.

There was plenty of single yarn, so after plying the slubby single with plain single, to create a two-ply, I three-plied the plain single, silk single, and Kidsilk Haze single. Of course, I ran out of one of those singles before the others, so I made a two-ply with the plain and Kidsilk Haze until I ran out of the latter, then finished with a two-ply of just the plain.

A new (to me) thing I tried was steaming the finished yarn instead of soaking it, to set the twist. My SO had loaned me his handheld steamer and I watched a couple of YouTube videos in preparation. I guess it worked okay - my yarn tends to be rather balanced once I am done plying, but it did feel fuller when I finished.

I ended up with a lot of yarn:

- 3-ply plain/silk/Kidsilk: 136 yds (176 g)

- 2-ply plain/Kidsilk: 20 yds (16 g)

- 2-ply plain/plain: 18 yds (11g)

- 2-ply slub/plain: 136 yds (111g)

- 2-ply wrapped slub/plain: 64 yds (59 g)

So what shall I make with all this? The roving is soft so the slubby yarn is soft, so it might be a nice woven or knitted scarf. The yarns with the silk and Kidsilk Haze has a tougher feel, though. I will have to let the yarn "age" a bit while I consider my options. Any suggestions?

Saturday, November 23, 2019

Everything is an ordeal

Sometimes just getting off the couch takes a humongous amount of effort because of my bum hip. I've been trying to keep up with everything, but balls keep dropping. The weather is not helping, as the dogs drag in fresh dirt which quickly cancels vacuuming and mopping efforts. Last minute grandma duty saps my energy. At least I have an excuse for the holidays this year; I decided it is time for me to be invited to Thanksgiving, not do Thanksgiving.

Knitting: I'm up to the heels on the socks. They are my traveling project, but I have to turn heels in the quiet of my own home. The L-Bag looks better with a stripe of pale tan between the walnut and henna bands.

Spinning: I finished the Montage Medley spinning and plying (separate post pending). I tried something new to set the twist: steam.

Needle felting: Trying to make progress on the fairy house from the last class I took, but I'm a bit stuck on getting the roof on. Today my granddaughter and I collaborated (new vocabulary word) on the xmas tree ornament and her bunny Peep. She is also fixated on Pickle the Dinosaur, which of course is sold out, so we've been needle felting Dill, Pickle's little sister.

It's amazing how time consuming yet engrossing needle felting is. I keep thinking of new things to make using wool and a barbed needle. So many projects, so little time!

Knitting: I'm up to the heels on the socks. They are my traveling project, but I have to turn heels in the quiet of my own home. The L-Bag looks better with a stripe of pale tan between the walnut and henna bands.

Spinning: I finished the Montage Medley spinning and plying (separate post pending). I tried something new to set the twist: steam.

Needle felting: Trying to make progress on the fairy house from the last class I took, but I'm a bit stuck on getting the roof on. Today my granddaughter and I collaborated (new vocabulary word) on the xmas tree ornament and her bunny Peep. She is also fixated on Pickle the Dinosaur, which of course is sold out, so we've been needle felting Dill, Pickle's little sister.

It's amazing how time consuming yet engrossing needle felting is. I keep thinking of new things to make using wool and a barbed needle. So many projects, so little time!

Saturday, November 16, 2019

Shoulda swatched

When I reached the shaping portion of the pattern for the L-Bag, I discovered that I had lost two stitches somewhere along the way. That, plus a couple of other things I did not like, led me to ripping back to almost the beginning. The two things I did not like were the two rounds of green around each band of yellow - rather have just one round - and the lack of any break between the walnut and the henna - so I'm adding a round of light tan. As I type this, however, I am wondering what one round will look like vs. two rounds once the bag is felted. If I had swatched, I might have the answer. It is never too late to swatch, so maybe I will just do it.

Knitting: See above for status of L-Bag; the socks are about halfway to the heel (I knit toe-up).

Spinning: Yes! I am spinning again, even though the studio is not completely put together yet. I've been working with a montage of mill ends, practicing slubby yarn, silk reinforced singles, even Kidsilk Haze reinforced singles.

Needle felting: My granddaughter and I messed around with needle felting this week. Her thing morphed into a bunny Peep; I was trying to make an xmas ornament using a cookie cutter as a pattern, with limited success.

Weaving: No actual weaving occurred. However, I am planning a fall banner of sorts that will include some of the things I learned at the dimensional weaving workshop.

Fiber prep: At this week's spinning guild meeting, we practiced blending colors using drum carders. I blended blue and white to create a light blue, red and blue to make purple, and red, blue, and white for lilac.

Both my guild meetings in December are xmas parties, which I am planning to skip. Hobbling around is getting more and more difficult. This past week, my "caregivers" and I attended a pre-op information session for hip replacement surgery. I am SOOOO ready!

Knitting: See above for status of L-Bag; the socks are about halfway to the heel (I knit toe-up).

Spinning: Yes! I am spinning again, even though the studio is not completely put together yet. I've been working with a montage of mill ends, practicing slubby yarn, silk reinforced singles, even Kidsilk Haze reinforced singles.

Needle felting: My granddaughter and I messed around with needle felting this week. Her thing morphed into a bunny Peep; I was trying to make an xmas ornament using a cookie cutter as a pattern, with limited success.

Weaving: No actual weaving occurred. However, I am planning a fall banner of sorts that will include some of the things I learned at the dimensional weaving workshop.

Fiber prep: At this week's spinning guild meeting, we practiced blending colors using drum carders. I blended blue and white to create a light blue, red and blue to make purple, and red, blue, and white for lilac.

Both my guild meetings in December are xmas parties, which I am planning to skip. Hobbling around is getting more and more difficult. This past week, my "caregivers" and I attended a pre-op information session for hip replacement surgery. I am SOOOO ready!

Saturday, November 09, 2019

Help me, help me

I'm used to being independent. Ordinarily, I find it difficult to ask anyone for help. While awaiting surgery for hip replacement, though, I have been forced to lean on others, literally and figuratively. Yesterday my granddaughter mopped my kitchen floor, today my SO weeded the area where my wonderful gold mop grows. He is being very patient with me as our dates devolve to lunch and running errands; he's particularly helpful at Costco where they seem to move products around, especially this time of year when they need more room for xmas crap.

My daughter and son-in-law and SO came over last Sunday to finish moving stuff around, but I have made no more progress on the new fiber arts studio because, frankly, the rest of the house is a pit. The living room and dining room are now under control; next is the family room and kitchen. Maybe THEN I will get back to the studio. I miss spinning.

Knitting: Progress has been made on both the socks and the L-Bag. The latter has reached the shaping phase, but of course the stitch counts are not coming out right.

Weaving: The yarn arrived and is exactly what I need. Now to just get going again.

In an attempt to uncover the coffee table in the living room, I have designated the recliner as my "knitting station", complete with Ott light to show the way. My daughter pointed out that until I have a place for everything and everything in its place, I am a Marie Kondo FAIL. I will get there someday.

My daughter and son-in-law and SO came over last Sunday to finish moving stuff around, but I have made no more progress on the new fiber arts studio because, frankly, the rest of the house is a pit. The living room and dining room are now under control; next is the family room and kitchen. Maybe THEN I will get back to the studio. I miss spinning.

Knitting: Progress has been made on both the socks and the L-Bag. The latter has reached the shaping phase, but of course the stitch counts are not coming out right.

Weaving: The yarn arrived and is exactly what I need. Now to just get going again.

In an attempt to uncover the coffee table in the living room, I have designated the recliner as my "knitting station", complete with Ott light to show the way. My daughter pointed out that until I have a place for everything and everything in its place, I am a Marie Kondo FAIL. I will get there someday.

Sunday, November 03, 2019

Best laid plans

I wanted to turn one of my spare bedrooms into the exercise/TV room. Toward that end, I got rid of the double bed in there, replaced the aging carpet with laminate, painted the walls, etc. and planned to move the sofa bed there. My house is well built but it has a few design flaws, and one of them is the configuration of the bedroom doorways. My daughter and her husband came over and measured and discussed and decided there was no way to get the sofa bed into that room. So onto Plan B: swap the fiber studio with the exercise/TV room since the sofa bed was already in the studio.

So that is what I have been doing this week. With the help of my SO, we have been schlepping stuff back and forth through the house. There are only a few 2-person items left to move (TV and its stand, elliptical, desk) which should be taken care of today. Then I can rearrange the old bedroom/new studio and get back to work.

I actually think this arrangement will work out better. One thing the bedroom has that the old studio does not is a closet. Crap expands to fill the space available, but now I can hide most of that crap away. Also, I was not sure what to do with the elliptical, but there is plenty of room in the old studio/new den.

Knitting: Bought the yarn I needed for toes and heels at Simply Socks, knit the toes (one twice), and am ready to forge ahead on the next pair of socks. Still working on the L-Bag.

Weaving: While emptying out the old studio, I found the missing ball band! I ordered the necessary rug yarn from Yarn Barn of Kansas, so now the woven bag project can progress.

Dyeing: Even though pokeweed berries are not a good dye source, I like to play around with them. I have been harvesting some (and leaving plenty for the robins and bluebirds). They are too soft to pick, so I tried freezing some on their stems but drying them on screens in the garage seems to work best.

So that is what I have been doing this week. With the help of my SO, we have been schlepping stuff back and forth through the house. There are only a few 2-person items left to move (TV and its stand, elliptical, desk) which should be taken care of today. Then I can rearrange the old bedroom/new studio and get back to work.

I actually think this arrangement will work out better. One thing the bedroom has that the old studio does not is a closet. Crap expands to fill the space available, but now I can hide most of that crap away. Also, I was not sure what to do with the elliptical, but there is plenty of room in the old studio/new den.

Knitting: Bought the yarn I needed for toes and heels at Simply Socks, knit the toes (one twice), and am ready to forge ahead on the next pair of socks. Still working on the L-Bag.

Weaving: While emptying out the old studio, I found the missing ball band! I ordered the necessary rug yarn from Yarn Barn of Kansas, so now the woven bag project can progress.

Dyeing: Even though pokeweed berries are not a good dye source, I like to play around with them. I have been harvesting some (and leaving plenty for the robins and bluebirds). They are too soft to pick, so I tried freezing some on their stems but drying them on screens in the garage seems to work best.

Friday, October 25, 2019

Yarn needed

What sometimes happens when I am knitting/weaving/spinning, I hit a snag of one sort or another. Sometimes I need more yarn, sometimes I need more knowledge, sometimes I am just disappointed in how whatever I am working on is turning out. The latter is the worst because then I am torn between just finishing it anyway or permanently abandoning the project. Any suggestions?

Knitting: Finished the socks; can't start another pair until I find some matching yarn in a solid color for the heels and toes. Started an L-Bag, using some of my naturally dyed yarn (walnut, onion skins, henna).

Needle felting: still working on the fairy house.

Spinning: Plied the remnants from the gradient project, just to empty out the bobbins.

Tomorrow I am dropping by Simply Socks to find some yarn for heels and toes. The bag I am weaving is held up because I need more of the dark brown but can't find the ball band with the colorway information. I don't usually throw ball bands away but this one is definitely MIA.

Knitting: Finished the socks; can't start another pair until I find some matching yarn in a solid color for the heels and toes. Started an L-Bag, using some of my naturally dyed yarn (walnut, onion skins, henna).

Needle felting: still working on the fairy house.

Spinning: Plied the remnants from the gradient project, just to empty out the bobbins.

Tomorrow I am dropping by Simply Socks to find some yarn for heels and toes. The bag I am weaving is held up because I need more of the dark brown but can't find the ball band with the colorway information. I don't usually throw ball bands away but this one is definitely MIA.

Thursday, October 24, 2019

Garter rib socks in browns

A while back I knit my SO a pair of socks that were mostly walnut with dark brown toes, heels, and cuffs. There seemed to be enough yarn left over for another pair, so I knit them in dark brown with walnut toes, heels, and cuffs. The former were in baby cables, the latter in garter rib.

Pattern: Short-row toe and heel basic socks, by Wendy D. Johnson, and garter rib, by Charlene Schurch.

Yarn: S.R. Kertzer On Your Toes 4 Ply with Aloe Vera, in brown, and unknown base yarn, hand dyed with black walnut, by Little Shop of Spinning

Needles: US1

Modifications: not really

Ordinarily, I do not make the cuffs so long, but I ran out of the dark brown yarn. Usually I switch to a 1x1 or 2x2 ribbing for the cuff, but this time just continued the garter rib. I hope they are tight enough to keep the socks up. If not, I can easily reknit the cuffs, an advantage of toe-up socks.

Now if only the weather would cool off enough for wearing wool!

Pattern: Short-row toe and heel basic socks, by Wendy D. Johnson, and garter rib, by Charlene Schurch.

Yarn: S.R. Kertzer On Your Toes 4 Ply with Aloe Vera, in brown, and unknown base yarn, hand dyed with black walnut, by Little Shop of Spinning

Needles: US1

Modifications: not really

Ordinarily, I do not make the cuffs so long, but I ran out of the dark brown yarn. Usually I switch to a 1x1 or 2x2 ribbing for the cuff, but this time just continued the garter rib. I hope they are tight enough to keep the socks up. If not, I can easily reknit the cuffs, an advantage of toe-up socks.

Now if only the weather would cool off enough for wearing wool!

Friday, October 18, 2019

Still not much progress

Cleaning for visitors, then visitors took up a goodly portion of this week, plus errands and some surgery prep. I don't always get a flu shot, tried to schedule one at my GP's office but the phone nurse bent over backwards to keep me away (I'm assuming they are very busy this time of year), so I went to Walgreens. Then my SO and I went in search of HUGE jammy bottoms for me to lounge around in while recovering (they have to be loose enough to go over bandaging and support hose). Needing a hip replacement has made me more empathetic toward those with chronic pain.

Spinning: got into a tiff with one of my spinning wheels while plying the slubby yarn, so I started spinning more skinny singles but with silk.

Knitting: STILL need to finish up Veronika; almost done with the socks.

Needle felting: Attended another needle felting workshop and have continued to work on the project from that.

At one point, my SO and I discussed attending the Handweavers Guild of America Convergence in Knoxville next summer, but quite frankly, I am burnt out on workshops. This year I attended one at Jay County, two at the Michigan Fiber Festival, two from the local parks department, and a two-day one with the local weaving guild which caused me to miss one with the local spinning guild. Instead, we are thinking of vising Storm King Art Center. My guy happily follows me to fiber fests (he's a photographer, so keeps plenty busy on his own); I decided we need to go somewhere important to him this time.

Spinning: got into a tiff with one of my spinning wheels while plying the slubby yarn, so I started spinning more skinny singles but with silk.

Knitting: STILL need to finish up Veronika; almost done with the socks.

Needle felting: Attended another needle felting workshop and have continued to work on the project from that.

At one point, my SO and I discussed attending the Handweavers Guild of America Convergence in Knoxville next summer, but quite frankly, I am burnt out on workshops. This year I attended one at Jay County, two at the Michigan Fiber Festival, two from the local parks department, and a two-day one with the local weaving guild which caused me to miss one with the local spinning guild. Instead, we are thinking of vising Storm King Art Center. My guy happily follows me to fiber fests (he's a photographer, so keeps plenty busy on his own); I decided we need to go somewhere important to him this time.

Sunday, October 13, 2019

Another day, another workshop

Saturday I attended yet another workshop in needle felting. Same instructor, same fiber art, yet I still learned something new. The class project was a bit ambitious for 3.5 hours - I have a long way to go - but am confident about what I am doing. I will post more details about the Fairy House Lamp once I'm done.

I'm trying to get somewhat ready for some visitors Tuesday - vacuum, dust, etc. - yet today just HAD to take a nap. I was knitting on the socks and literally dozing off between stitches. Has that happened to any of you?

I'm trying to get somewhat ready for some visitors Tuesday - vacuum, dust, etc. - yet today just HAD to take a nap. I was knitting on the socks and literally dozing off between stitches. Has that happened to any of you?

Friday, October 11, 2019

Not much progress report

This week has been a bit of a struggle fiberwise (and other wise). My SO came over and helped me with some yardwork (including dog-proofing the compost bin), I had to visit a physical therapist as a prelude to hip replacement surgery (that is scheduled in December), a while back Beau the Feline Destroyer of All Things Nice ruined the caned bottoms of ALL the dining room chairs (you couldn't sit on them without getting splinters in your butt) and I finally got them recovered this week, the contractors finished the updates to the bathrooms, etc. Always something going on.

Spinning: plied some of the skinny single with the slubby yarn. It is really soft!

Knitting: still need to finish up Veronika; into the cuffs on the socks.

Weaving: worked a bit on my piece from the dimensional weaving workshop.

Needle felting: finished up the pumpkin from the previous workshop - and taking another needle felting workshop tomorrow!

I follow Rebecca Mezoff, who is an accomplished tapestry weaver. She has a lot of Youtube vids including one that contains excellent advice (which she attributes to Tommye Scanlin, another accomplished weaver): Weave every darn day. I spin almost every day, I knit almost every day, I don't care if I needle felt every day but I think I will needle felt a sign that says, WEAVE EVERY DAY because that is something I don't do but wish I did. Or maybe I should tapestry weave the sign! Maybe then it would sink in.

Spinning: plied some of the skinny single with the slubby yarn. It is really soft!

Knitting: still need to finish up Veronika; into the cuffs on the socks.

Weaving: worked a bit on my piece from the dimensional weaving workshop.

Needle felting: finished up the pumpkin from the previous workshop - and taking another needle felting workshop tomorrow!

I follow Rebecca Mezoff, who is an accomplished tapestry weaver. She has a lot of Youtube vids including one that contains excellent advice (which she attributes to Tommye Scanlin, another accomplished weaver): Weave every darn day. I spin almost every day, I knit almost every day, I don't care if I needle felt every day but I think I will needle felt a sign that says, WEAVE EVERY DAY because that is something I don't do but wish I did. Or maybe I should tapestry weave the sign! Maybe then it would sink in.

Thursday, October 10, 2019

Dimensional Weaving workshop

Last Friday and Saturday I spent six hours a day weaving. If I did that every day, I would get a LOT done! I would also be stiff as a board. Even though we stretched periodically, I felt nearly crippled by the end, happy to come home and lay on the floor for a while.

The instructor was Martina Celerin (web site may be found HERE). Almost all the materials she uses are scavenged from here, there, and everywhere, including Goodwill by the Pound. Consequently, most of the fiber was acrylic yarn, not my favorite material to work with. But there were also beads, shells, crinoids, feather boas, leather strips, etc.

No experience was necessary to take this class. You also did not need to bring or buy any equipment, as Martina supplied looms (built from scrap lumber), shuttles and pick-up sticks (made from yard sticks), and beaters (real metal forks). At the end of the class, I did purchase my equipment, partly because I was not finished but also because I seem to have become a collector of frame looms.

I came with an idea and some of my own materials, but the narrow loom precluded following that path. The second day we discovered a feature of these looms: because the nails run all the way to the edge, two looms may be clamped together, to form a wider one.

All it takes is a drill, a couple of nuts, and two long bolts.

While everyone else seemed to be creating pretty, 3-D pictures, I somehow ended up with monsters (ala Make It Mighty Ugly, by Kim P. Werker). The mummy was supposed to be a skeleton (everyone else was making trees and/or branches), but once I started wrapping, I just kept wrapping until a mummy appeared. I needle felted the pumpkin from some roving I brought, now that I know how to do that from a PREVIOUS WORKSHOP. (I wish I had used candy corn colors for the borders.)

At one point, while waiting on the instructor to cover the next technique, I started weaving from the other end of the loom, creating a gradient sunrise.

Since we started weaving right next to the nails, one end of the piece(s) will naturally have no fringe. And right now I can't recall the details about the other end except that each pair of warp threads needs to be tied together. Ends on the back of the piece can be tacked down with a glue gun.

I'm not going to start weaving like Martina, but I'm sure the techniques I learned will inform my own weaving. It's easy to get bogged down with weaving rules when there really aren't any. Or maybe a better way of saying that is, Learn the rules, then break them.

The instructor was Martina Celerin (web site may be found HERE). Almost all the materials she uses are scavenged from here, there, and everywhere, including Goodwill by the Pound. Consequently, most of the fiber was acrylic yarn, not my favorite material to work with. But there were also beads, shells, crinoids, feather boas, leather strips, etc.

No experience was necessary to take this class. You also did not need to bring or buy any equipment, as Martina supplied looms (built from scrap lumber), shuttles and pick-up sticks (made from yard sticks), and beaters (real metal forks). At the end of the class, I did purchase my equipment, partly because I was not finished but also because I seem to have become a collector of frame looms.

I came with an idea and some of my own materials, but the narrow loom precluded following that path. The second day we discovered a feature of these looms: because the nails run all the way to the edge, two looms may be clamped together, to form a wider one.

All it takes is a drill, a couple of nuts, and two long bolts.

While everyone else seemed to be creating pretty, 3-D pictures, I somehow ended up with monsters (ala Make It Mighty Ugly, by Kim P. Werker). The mummy was supposed to be a skeleton (everyone else was making trees and/or branches), but once I started wrapping, I just kept wrapping until a mummy appeared. I needle felted the pumpkin from some roving I brought, now that I know how to do that from a PREVIOUS WORKSHOP. (I wish I had used candy corn colors for the borders.)

At one point, while waiting on the instructor to cover the next technique, I started weaving from the other end of the loom, creating a gradient sunrise.

Since we started weaving right next to the nails, one end of the piece(s) will naturally have no fringe. And right now I can't recall the details about the other end except that each pair of warp threads needs to be tied together. Ends on the back of the piece can be tacked down with a glue gun.

I'm not going to start weaving like Martina, but I'm sure the techniques I learned will inform my own weaving. It's easy to get bogged down with weaving rules when there really aren't any. Or maybe a better way of saying that is, Learn the rules, then break them.

Saturday, October 05, 2019

A day late

Sorry I am late in my weekly status report, but I have what I consider a good excuse: I was in a "dimensional weaving" workshop Friday and today. More on that later. Because of this workshop, I missed a local workshop on "bucket" dyeing. So many workshops, so little time!

Knitting: No progress on the Veronika cardigan. Nearing the cuff on the socks.

Spinning: Finished spinning a skinny single to ply with the slubby singles.

Weaving: A little progress on the rya tote bag. I actually wove a one-inch section without making a mistake!

Needle felting: Finishing touches on the pumpkin from the needle felting workshop, a few more to go and that will be done. Needle felted a little sheep and started an alpaca/llama (not sure yet which it will be.)

Knitting: No progress on the Veronika cardigan. Nearing the cuff on the socks.

Spinning: Finished spinning a skinny single to ply with the slubby singles.

Weaving: A little progress on the rya tote bag. I actually wove a one-inch section without making a mistake!

Needle felting: Finishing touches on the pumpkin from the needle felting workshop, a few more to go and that will be done. Needle felted a little sheep and started an alpaca/llama (not sure yet which it will be.)

Saturday, September 28, 2019

Needle felted pumpkin

Friday morning I took a workshop, officially titled "Needle Felt a Fairy Tale Pumpkin", through our local parks and rec department. I wasn't all that interested in needle felting, enrolled so I can transfer knowledge to my granddaughter, but this fiber art is not only fun but addicting.

The instructor Sue Powe belongs to my spinning guild. During the show-and-tell portion of our meetings, she invariably has a sculpture to share. She also sells them at fiber fests and through a local retailer, Fae's Closet. Whimsy is her forte.

(In the above picture are two of Sue's sculptures, a sad snowman and a sheep spindling her own wool. The red dinosaur in the back was created previously by one of the students. The colorway of the wool is "Pumpkin Spice" - of course.)

Sue's background includes ergonomics, so she helped us learn how to felt without developing carpal tunnel. We examined lots of wool before getting down to business. Repeatedly stabbing a hunk of wool sounds boring and tedious, but for some reason it is fun and relaxing - as long as no fingers get pricked. My pumpkin isn't quite done yet - I want to add more to the body. Also, I made the mistake of leaving my pumpkin on the kitchen counter while I ate lunch. Beau the Feline Destroyer of All Things Nice got hold of it and did some damage. Fortunately, the pumpkin is repairable.

There were only four students in the class, so we received lots of individual attention. Two students were age 11 and 12, and their pumpkins turned out great. I also now have a couple of ideas about how to direct my granddaughter's needle felting: use cookie cutters to create shapes and felt on top of Styrofoam balls for xmas ornaments. Stay tuned for more needle felting.

The instructor Sue Powe belongs to my spinning guild. During the show-and-tell portion of our meetings, she invariably has a sculpture to share. She also sells them at fiber fests and through a local retailer, Fae's Closet. Whimsy is her forte.

(In the above picture are two of Sue's sculptures, a sad snowman and a sheep spindling her own wool. The red dinosaur in the back was created previously by one of the students. The colorway of the wool is "Pumpkin Spice" - of course.)

Sue's background includes ergonomics, so she helped us learn how to felt without developing carpal tunnel. We examined lots of wool before getting down to business. Repeatedly stabbing a hunk of wool sounds boring and tedious, but for some reason it is fun and relaxing - as long as no fingers get pricked. My pumpkin isn't quite done yet - I want to add more to the body. Also, I made the mistake of leaving my pumpkin on the kitchen counter while I ate lunch. Beau the Feline Destroyer of All Things Nice got hold of it and did some damage. Fortunately, the pumpkin is repairable.

There were only four students in the class, so we received lots of individual attention. Two students were age 11 and 12, and their pumpkins turned out great. I also now have a couple of ideas about how to direct my granddaughter's needle felting: use cookie cutters to create shapes and felt on top of Styrofoam balls for xmas ornaments. Stay tuned for more needle felting.

Friday, September 27, 2019

TW3

Brief wrap-up of the week that was.

Knitting: Finished the knitting of the Veronika cardigan, and it is blocked as well. Just need to do a little mattress stitching. The socks are ongoing.

Spinning: I'm spinning singles to ply with the slubby yarn I've been trying to master.

Weaving: Put on my big girl pants and fixed the broken warp. That success was followed by a badly executed rya row. I'll get the hang of it yet.

Needle felting: Took a 2.5 hour workshop, created a 3-D pumpkin. Fun and addicting!

Knitting: Finished the knitting of the Veronika cardigan, and it is blocked as well. Just need to do a little mattress stitching. The socks are ongoing.

Spinning: I'm spinning singles to ply with the slubby yarn I've been trying to master.

Weaving: Put on my big girl pants and fixed the broken warp. That success was followed by a badly executed rya row. I'll get the hang of it yet.

Needle felting: Took a 2.5 hour workshop, created a 3-D pumpkin. Fun and addicting!

Friday, September 20, 2019

TW3

(Is anyone else old enough to remember the TV show That Was the Week that Was? AKA TW3? Anyone? Anyone?)

In regards to yesterday's post, I'm not sure I could keep up with daily reports on my progress. Perhaps once a week is doable? We'll give that a try.

So what am I working on?

Knitting: In the homestretch of the Veronika cardigan. All that is left is ribbing along the back, plus a little bit of sewing. A pair of socks is halfway up the calf.

Spinning: I'm trying to teach myself to make slubby yarn. Yesterday I tried wrapping the yarn with thread as I spun. Tricky!

Weaving: I'm working on a rya bag on my frame loom, but a couple of days ago Ibroke cut a warp thread - ugh!

Dyeing: Picking clusters of pokeweed berries; froze some, put some in the garage on a drying rack, as they tend to dry on the stem anyway.

In regards to yesterday's post, I'm not sure I could keep up with daily reports on my progress. Perhaps once a week is doable? We'll give that a try.

So what am I working on?

Knitting: In the homestretch of the Veronika cardigan. All that is left is ribbing along the back, plus a little bit of sewing. A pair of socks is halfway up the calf.

Spinning: I'm trying to teach myself to make slubby yarn. Yesterday I tried wrapping the yarn with thread as I spun. Tricky!

Weaving: I'm working on a rya bag on my frame loom, but a couple of days ago I

Dyeing: Picking clusters of pokeweed berries; froze some, put some in the garage on a drying rack, as they tend to dry on the stem anyway.

Thursday, September 19, 2019

Do you fiber every day?

A while back I wasn't spinning yarn because I had some very nice roving but didn't want to spin it until I became a better spinner. Then two things occurred to me:

So I pulled out a big ball of luscious Lincoln top and spun away. The more I spun, the better I got. I also lost my dread of plying because I had to ply those singles to free up bobbins. I am not the best spinner in the world, but I feel much more comfortable at the wheel now.

When I first returned to knitting oh-so-many years ago, I would knit about anything, just to be knitting. I knit at work during meetings, I knit in the car (while a passenger), I knit on planes, in hotel rooms, at home in front of the TV. Then I just sort of stopped. Learning to weave might have had something to do with it, but I think it more likely was the realization I had knit a lot of stuff that not only did I not want to wear, but nobody else did either.

I faced the same dilemma with weaving as I did with spinning: it was hard to just be willing to DO IT and SUCK AT IT for a while. I am still a long way from feeling at ease at a loom, as every project is a learning experience, but it's getting better.

Being retired has provided me with enough time to practice fiber arts every day. It is not unusual for me to at least spin a bit in the morning and knit a bit in the afternoon. Now I would like to weave a bit every day as well, plus process the multiple fleeces. Sometimes it feels like I never finish anything, but bit by bit, I will get there.

So I'm contemplating somehow reporting on this blog what I work on each day. It will have to be a brief summary, perhaps in a sidebar, or it won't happen. My goal is twofold: to have a record of sorts of my daily fiber output and to demonstrate that slow and steady completes the project.

When I mentioned to my fiber friends that I try to spin for 30 minutes a day and knit for 30 minutes a day, I get what are surprising-to-me negative reactions, like I'm turning a joy into a duty. But the more I spin, knit, weave, etc., the more joy I get from fiber. Writers write every day (at least, the successful ones do). I think fiber artists could take the same approach.

Does this resonate with you? Or am I being insufferable?

- I wouldn't become a better spinner unless I actually did some spinning

- It is easier to learn to spin using good roving than bad roving

So I pulled out a big ball of luscious Lincoln top and spun away. The more I spun, the better I got. I also lost my dread of plying because I had to ply those singles to free up bobbins. I am not the best spinner in the world, but I feel much more comfortable at the wheel now.

When I first returned to knitting oh-so-many years ago, I would knit about anything, just to be knitting. I knit at work during meetings, I knit in the car (while a passenger), I knit on planes, in hotel rooms, at home in front of the TV. Then I just sort of stopped. Learning to weave might have had something to do with it, but I think it more likely was the realization I had knit a lot of stuff that not only did I not want to wear, but nobody else did either.

I faced the same dilemma with weaving as I did with spinning: it was hard to just be willing to DO IT and SUCK AT IT for a while. I am still a long way from feeling at ease at a loom, as every project is a learning experience, but it's getting better.

Being retired has provided me with enough time to practice fiber arts every day. It is not unusual for me to at least spin a bit in the morning and knit a bit in the afternoon. Now I would like to weave a bit every day as well, plus process the multiple fleeces. Sometimes it feels like I never finish anything, but bit by bit, I will get there.

So I'm contemplating somehow reporting on this blog what I work on each day. It will have to be a brief summary, perhaps in a sidebar, or it won't happen. My goal is twofold: to have a record of sorts of my daily fiber output and to demonstrate that slow and steady completes the project.

When I mentioned to my fiber friends that I try to spin for 30 minutes a day and knit for 30 minutes a day, I get what are surprising-to-me negative reactions, like I'm turning a joy into a duty. But the more I spin, knit, weave, etc., the more joy I get from fiber. Writers write every day (at least, the successful ones do). I think fiber artists could take the same approach.

Does this resonate with you? Or am I being insufferable?

Sunday, September 08, 2019

Spinning gray scale gradient yarn

A while back, I was playing around with some tapestry techniques. There are several ways to introduce gradient effects to a tapestry, but the book's method was a big fail for me: separate plies from (commercial) yarn and combine the plies of different tones to create gradients. The yarn I was working with snarled and snapped at me when I tried this. Then it occurred to me that, since I'm a spinner, I can create my own gradient yarns. Taking a workshop on spinning gradient yarns didn't hurt, either.

Starting with a range of roving, from black to white, I 3-plied a bunch of combinations:

Starting with a range of roving, from black to white, I 3-plied a bunch of combinations:

- black-black-black

- black-black-dark gray

- black-dark gray-dark gray

- dark gray-dark gray-dark gray

- dark gray-dark gray-medium gray

- dark gray-medium gray-medium gray

- medium gray-medium gray-medium gray

- medium gray-medium gray-light gray

- medium gray-light gray-light gray

- light gray-light gray-light gray

- light gray-light gray-white

- light gray-white-white

- white-white-white

Tuesday, September 03, 2019

Dye test with blue false indigo, part 1

I like indigo as a color, but I am not thrilled with the process for dyeing yarn with it. I've experienced it only in dye workshops (described here and here), never tried it myself at home. It requires several steps and a certain amount of care or you can easily ruin the dye bath.

However, I do have blue false indigo (Baptisia australis) growing (and growing and GROWING - it spreads by rhizomes) in my yard. Even though false indigo is not related to any of the true indigo producing plants, I figured it would not hurt to test it.

But first, I did a search online to see if anyone else had tried this experiment. I can find references about using false indigo for dyeing (and references that say it is NOT a dye source), but I did not notice anything specific. Please correct me if I am wrong.

I am not quite done with this experiment, but I decided to show you what I have so far. I didn't do anything too fancy, just in case my tests were a total bust. I used alum mordanted Cascade 220 in dye baths containing the blossoms, leaves, stems, pods, or seeds. For each plant part, I poured boiling water over about 12g the plant part, let it set overnight, strained the dye bath, added about 2 yards of yarn, popped it in the microwave for a minute, again let it set overnight, and then rinsed the yarn. The results were a bit surprising.

No blue, but several shades of green and yellow. The only plant part remaining to test is the root. I'm waiting for the plant to die back this fall before digging up some samples.

Now my interest is piqued. What if I used no mordant or a different mordant? Modified the results post dyeing using an acid or alkaline bath? Used tap water, distilled water, well water, rain water? How light fast are the results? Stayed tooned!

However, I do have blue false indigo (Baptisia australis) growing (and growing and GROWING - it spreads by rhizomes) in my yard. Even though false indigo is not related to any of the true indigo producing plants, I figured it would not hurt to test it.

But first, I did a search online to see if anyone else had tried this experiment. I can find references about using false indigo for dyeing (and references that say it is NOT a dye source), but I did not notice anything specific. Please correct me if I am wrong.

I am not quite done with this experiment, but I decided to show you what I have so far. I didn't do anything too fancy, just in case my tests were a total bust. I used alum mordanted Cascade 220 in dye baths containing the blossoms, leaves, stems, pods, or seeds. For each plant part, I poured boiling water over about 12g the plant part, let it set overnight, strained the dye bath, added about 2 yards of yarn, popped it in the microwave for a minute, again let it set overnight, and then rinsed the yarn. The results were a bit surprising.

|

| From left, blossoms, leaves, stems, pods, seeds |

No blue, but several shades of green and yellow. The only plant part remaining to test is the root. I'm waiting for the plant to die back this fall before digging up some samples.

Now my interest is piqued. What if I used no mordant or a different mordant? Modified the results post dyeing using an acid or alkaline bath? Used tap water, distilled water, well water, rain water? How light fast are the results? Stayed tooned!

Monday, September 02, 2019

Fresh spun yarn - alpaca

Even though I don't post here very often, I do some kind of fiber art activity everyday. It just takes me a while to get to the point of showing you something. Today is the result of days of spinning and plying some alpaca.

In 2009, I purchased about 8oz of alpaca at our local Johnny Appleseed Festival. It came from an animal named Spartacus who lives on the Michel Century Farm in Huntington, IN. Alpaca fleece has no lanolin, is smoother than sheep wool, and is very warm. Spartacus was a rose gray huacaya. Since the fiber felt finer than wool, I spun it worsted at a ratio of 8:1 on my Joy2 Ashford wheel. The result is 330 yards of 3-ply. (I haven't measured the WPI yet.)

Alpaca fiber supposedly does not need to be cleaned before spinning, BUT. The roving felt dirty, and my spinning fingers attest to the fact that is was dirty. Yet, when I soaked the yarn to set the twist, the water remained clear. I am making a mental note, however, to wash the yarn before I dye, knit, or weave with it. Even if I forget my mental note, the feel of the yarn should remind me.

In general, I am not a fan of alpaca. However, it's durable, resists pilling (VERY IMPORTANT TO ME!), blends well with other fibers, and dyes well. I may have to reconsider my bias.

In 2009, I purchased about 8oz of alpaca at our local Johnny Appleseed Festival. It came from an animal named Spartacus who lives on the Michel Century Farm in Huntington, IN. Alpaca fleece has no lanolin, is smoother than sheep wool, and is very warm. Spartacus was a rose gray huacaya. Since the fiber felt finer than wool, I spun it worsted at a ratio of 8:1 on my Joy2 Ashford wheel. The result is 330 yards of 3-ply. (I haven't measured the WPI yet.)

Alpaca fiber supposedly does not need to be cleaned before spinning, BUT. The roving felt dirty, and my spinning fingers attest to the fact that is was dirty. Yet, when I soaked the yarn to set the twist, the water remained clear. I am making a mental note, however, to wash the yarn before I dye, knit, or weave with it. Even if I forget my mental note, the feel of the yarn should remind me.

In general, I am not a fan of alpaca. However, it's durable, resists pilling (VERY IMPORTANT TO ME!), blends well with other fibers, and dyes well. I may have to reconsider my bias.

Thursday, August 22, 2019

Michigan Fiber Festival first timer

My SO and I traveled to Allegan MI for the Michigan Fiber Festival a week or so ago. We drove up on Monday and stayed until Friday (at the Hotel Allegan). I took two classes and he took one. No, he is not a fiber person; he is a photographer and took the cyanotype class. Enough fiber knowledge has rubbed off me onto him, though, so he was comfortable with the chitchat.

The workshops did not start until Wednesday, so we took advantage of the lovely weather to explore the environs. One thing the state of Michigan could use is more road signs. On Tuesday we tried to find Oval Beach but never figured out where to turn. We did manage to find the beach at Saugatuck Dunes State Park, but that involved a 3/4 mile hike from the parking lot to the water. Of course, we could have done a bit of research ahead of time, but we were trying to make do with maps and directions instead of GPS or Google Maps.

The beach itself was very narrow, looked like it had been carved out the dunes. My son told me the water level has been rising in Lake Michigan in recent years. We still enjoyed a nice swim, though. No toxic sludge.

A few places we ate: Root Cafe, Grill House (where you can grill your own steak but we did not - I fail to see the lure of that), and Mug Shots Coffeehouse.

Enough tourist stuff. Onto the festival!

FB posts on the Michigan Fiber Festival's page warned of many improvements, but since we were newbies, they were mostly lost on us. I didn't know where we would eat lunch, but there was a band-fund-raising snack bar on site with perfectly adequate breakfast and lunch items, although by the end of our stay, I was getting tired of chips. If I go again, I will probably bring my own food at least part of the time, using my brand new swag gift of an insulated bag.

My first class was "Scour like a Boss" with teacher Mary Egbert. I attended one of her classes at PlyAway last year, so I knew she would be a good instructor. For some reason, I neglected to take any photos (boo), but the class was very helpful. I have scoured a fleece before, found it quite the ordeal, but this class provided some good information, expert tips and tricks, and got me excited to scour some more fleece. (There are three in the garage, just waiting for my attention.) Not only did Mary do an excellent job, the others in the class had helpful hints, too.

The second class, Tapestry Weaving, taught by Rosemary Morningstar, was a disappointment. The folder included some graph paper, but we did no design. There was a list of basic techniques, but the instructor did not go over them. I was hoping for expert tips and tricks to add to my book learning, but that didn't happen. HOWEVER, we each received a nifty PVC pipe loom and some weaving tools. Also, the teacher did give us each individual attention.

The instructor had a bunch of books for us to peruse. My local library system has several, which I just picked up the other day. Also, she recommended Rebecca Mezoff's blog, which I already follow. In fact, I am planning to treat myself to one (or more) of Rebecca's online classes this fall/winter while I recover from hip replacement surgery.

I utilized my exposure to color theory to come up with this color scheme and had plans to continue with the weaving, but a few problems cropped up after I got home, so I just cut it off the loom. My frustrations with this class got me thinking about how I would teach tapestry weaving to beginners. Someone in my weaving guild suggested I do that for one of our Super Saturdays, and now I think I just might try that.

No fiber festival is complete without the opportunity to visit vendors and spend money. I was very good, didn't buy any yarn or roving or fleece, but did pick up a few items. These 14" birch DPNs are for trying with my knitting belt. I had not been able to find any longish needles for it above size US6, so I grabbed up a set of US7s and US8s. They are made by Twin Birch Products.

I swore I was not going to take up needle felting, BUT... after unsuccessfully trying to interest my granddaughter in a variety of crafts (she finds them too tedious), I hit the jackpot with needle felting (stab, stab, stab). Many years ago, I purchased some needle felting paraphernalia that I never used, but you know how it is with a new hobby - one never has enough tools or materials. I picked up a little needle felting kit for her (assembled by Phoenix Fiber Mill).

The felting needles I have are a six-pointer, a four-pointer, and a two-pointer, so I picked up several singles. (I don't know this vendor's name.) I also promised my granddaughter I would sign up for a class and transfer the knowledge to her. (The things we do for grandkids.)

Not so long ago, I read a post by Jillian Moreno (I think) that was on the Schacht web site (I think) about using storage spools - and I can't find that post. Anyway, I got it into my head that I needed not just storage spools but a spool winder. They seemed pricey enough that I assumed they came with a mechanism for distributing the yarn across the spool. While in Allegan for the festival, we stopped at the Baker Allegan Studios (a Schacht dealer) to find out more. Alas, there is not a mechanism for distributing the yarn, so I left empty handed (in part because I was so tired and hungry that I could not make a decision but also because they were having a giant yarn sale and I didn't want to get sucked in). At the festival, I did buy some wooden spools from A Wee Bit Warped. After arriving home, I realized I already have a set of spools like these but plastic, from when I purchased a boat shuttle that doesn't work with my loom. Oh, well. Now I have lots of spools.

Our plan for next summer is to visit the Handweavers Guild of America Convergence in Knoxville, TN. That's assuming there are classes/workshops I want to attend. If not, I would definitely go back to Allegan. So many classes, so little time! I think we missed a lot by skipping the weekend activities, too.

The workshops did not start until Wednesday, so we took advantage of the lovely weather to explore the environs. One thing the state of Michigan could use is more road signs. On Tuesday we tried to find Oval Beach but never figured out where to turn. We did manage to find the beach at Saugatuck Dunes State Park, but that involved a 3/4 mile hike from the parking lot to the water. Of course, we could have done a bit of research ahead of time, but we were trying to make do with maps and directions instead of GPS or Google Maps.

The beach itself was very narrow, looked like it had been carved out the dunes. My son told me the water level has been rising in Lake Michigan in recent years. We still enjoyed a nice swim, though. No toxic sludge.

A few places we ate: Root Cafe, Grill House (where you can grill your own steak but we did not - I fail to see the lure of that), and Mug Shots Coffeehouse.

Enough tourist stuff. Onto the festival!

FB posts on the Michigan Fiber Festival's page warned of many improvements, but since we were newbies, they were mostly lost on us. I didn't know where we would eat lunch, but there was a band-fund-raising snack bar on site with perfectly adequate breakfast and lunch items, although by the end of our stay, I was getting tired of chips. If I go again, I will probably bring my own food at least part of the time, using my brand new swag gift of an insulated bag.

My first class was "Scour like a Boss" with teacher Mary Egbert. I attended one of her classes at PlyAway last year, so I knew she would be a good instructor. For some reason, I neglected to take any photos (boo), but the class was very helpful. I have scoured a fleece before, found it quite the ordeal, but this class provided some good information, expert tips and tricks, and got me excited to scour some more fleece. (There are three in the garage, just waiting for my attention.) Not only did Mary do an excellent job, the others in the class had helpful hints, too.

The second class, Tapestry Weaving, taught by Rosemary Morningstar, was a disappointment. The folder included some graph paper, but we did no design. There was a list of basic techniques, but the instructor did not go over them. I was hoping for expert tips and tricks to add to my book learning, but that didn't happen. HOWEVER, we each received a nifty PVC pipe loom and some weaving tools. Also, the teacher did give us each individual attention.

The instructor had a bunch of books for us to peruse. My local library system has several, which I just picked up the other day. Also, she recommended Rebecca Mezoff's blog, which I already follow. In fact, I am planning to treat myself to one (or more) of Rebecca's online classes this fall/winter while I recover from hip replacement surgery.

I utilized my exposure to color theory to come up with this color scheme and had plans to continue with the weaving, but a few problems cropped up after I got home, so I just cut it off the loom. My frustrations with this class got me thinking about how I would teach tapestry weaving to beginners. Someone in my weaving guild suggested I do that for one of our Super Saturdays, and now I think I just might try that.

No fiber festival is complete without the opportunity to visit vendors and spend money. I was very good, didn't buy any yarn or roving or fleece, but did pick up a few items. These 14" birch DPNs are for trying with my knitting belt. I had not been able to find any longish needles for it above size US6, so I grabbed up a set of US7s and US8s. They are made by Twin Birch Products.

I swore I was not going to take up needle felting, BUT... after unsuccessfully trying to interest my granddaughter in a variety of crafts (she finds them too tedious), I hit the jackpot with needle felting (stab, stab, stab). Many years ago, I purchased some needle felting paraphernalia that I never used, but you know how it is with a new hobby - one never has enough tools or materials. I picked up a little needle felting kit for her (assembled by Phoenix Fiber Mill).

The felting needles I have are a six-pointer, a four-pointer, and a two-pointer, so I picked up several singles. (I don't know this vendor's name.) I also promised my granddaughter I would sign up for a class and transfer the knowledge to her. (The things we do for grandkids.)

Not so long ago, I read a post by Jillian Moreno (I think) that was on the Schacht web site (I think) about using storage spools - and I can't find that post. Anyway, I got it into my head that I needed not just storage spools but a spool winder. They seemed pricey enough that I assumed they came with a mechanism for distributing the yarn across the spool. While in Allegan for the festival, we stopped at the Baker Allegan Studios (a Schacht dealer) to find out more. Alas, there is not a mechanism for distributing the yarn, so I left empty handed (in part because I was so tired and hungry that I could not make a decision but also because they were having a giant yarn sale and I didn't want to get sucked in). At the festival, I did buy some wooden spools from A Wee Bit Warped. After arriving home, I realized I already have a set of spools like these but plastic, from when I purchased a boat shuttle that doesn't work with my loom. Oh, well. Now I have lots of spools.

Our plan for next summer is to visit the Handweavers Guild of America Convergence in Knoxville, TN. That's assuming there are classes/workshops I want to attend. If not, I would definitely go back to Allegan. So many classes, so little time! I think we missed a lot by skipping the weekend activities, too.

Monday, August 19, 2019

Jenny Dean and Wild Color - behind the scenes

I rely heavily on Jenny Dean's book Wild Color for natural dyeing, but my results rarely match what is in the book. Now I know why: the colors shown in the book are not from actual dye samples but from swatches matched to a Pantone chart. Dean had only so much control over what went into the book, as revealed in her recent blog post (which you can find HERE).

Dean claims the second revised edition of her self-published book “Colours from Nature” more closely matches how she currently dyes, so I guess I will have to get a copy of that and see what the differences are. Also, I would like her to know that while she was not able to get purples from hollyhock blossoms, I did using black hollyhocks.

I am really glad to have come across Dean's blog post because I am supposed to make a presentation about natural dyeing to my local weavers guild next March. Now I can point my fiber friends in the right direction. Serendipity, baby!

Dean claims the second revised edition of her self-published book “Colours from Nature” more closely matches how she currently dyes, so I guess I will have to get a copy of that and see what the differences are. Also, I would like her to know that while she was not able to get purples from hollyhock blossoms, I did using black hollyhocks.

I am really glad to have come across Dean's blog post because I am supposed to make a presentation about natural dyeing to my local weavers guild next March. Now I can point my fiber friends in the right direction. Serendipity, baby!

Friday, July 26, 2019

Famous last words

Sometimes I come back from a fiber festival with some luscious roving that is not labeled. If I'm lucky, there is a written receipt that describes what I purchased. Frequently, though, I just tell myself, I'll remember what this roving is. HA!

So today, having recently made a major purchase in roving from the under-new-ownership Little Shop of Spinning, I did a little housekeeping and tagged each ball of roving with the facts: breed and colorway. Well, some got facts on their tags. A few balls I purchased during the grand opening were not tagged, nor did the receipt specify what I had purchased, just what I paid. Those were labeled with guesses.

What, you may ask, do I plan to do with all those primary colors? Well, mix them, of course. Last year, at Ply Away, I took a class in what was supposed to be fiber prep but turned out to be an exercise in blending. That got me started down the path of why-look-for-the-perfect-color-of-roving-when-I-can-blend-my-own.

Back to those famous last words I'll remember. Before I learned to spin on a wheel, I made a genuine effort to spindle. Eventually, those spindles became part of my decor. I decided to try selling the spindles, but first had to remove the long-forgotten-where-it-came-from fiber from the spindles. And while I was at it, I decided to finish spinning the Shetland and ply it all off the bobbins (before I forget what is there).

From the left, white spindled yarn, gray spindled yarn, 2-ply Shetland, 3-ply Shetland, and a 3-ply skein of what I thought was carbonized bamboo. The reason I know it is not carbonized bamboo is because I came across the carbonized bamboo today, in a zip lock bag that included a LABEL. Meanwhile, the ball I spun that last skein from is probably 'Licorice' Corriedale that I thought I remembered I had but could not find, so I bought some more. This is one way that stashes grow.

Meanwhile, I am experimenting with gradient yarns for tapestry. One book I work from suggested taking the 3-ply commercial yarn one is working with and divide the plies, then combine them with other nearby colors of singles. Well, the commercial yarn I happened to be using at the time does not take kindly to being unplied and replied. Then I realized that I can create my own mixed color plies.

I have been spinning up white, three shades of gray, and black into singles, with a plan on combining the singles into a series of gradients. For the record, the white and black are Corriedale, the light and medium grays are Romney/Wesleydale, and the dark gray Wesleydale.

While looking up the links for this post, I found some photos that indicate the spindled yarn may be what came in the spindle kit from Louet. Some of that turned into a cowl that I used A LOT during the polar vortex. And I also see that the rose gray alpaca I thought I bought in Ohio actually found me here in the Fort during the Johnny Appleseed Festival. Maybe I should read my own blog to find out what's what in my stash.

So today, having recently made a major purchase in roving from the under-new-ownership Little Shop of Spinning, I did a little housekeeping and tagged each ball of roving with the facts: breed and colorway. Well, some got facts on their tags. A few balls I purchased during the grand opening were not tagged, nor did the receipt specify what I had purchased, just what I paid. Those were labeled with guesses.

What, you may ask, do I plan to do with all those primary colors? Well, mix them, of course. Last year, at Ply Away, I took a class in what was supposed to be fiber prep but turned out to be an exercise in blending. That got me started down the path of why-look-for-the-perfect-color-of-roving-when-I-can-blend-my-own.